Trick Factors To Consider for Creating Effective Forklift Safety Signs

When making reliable forklift safety indicators, it is important to consider several fundamental aspects that jointly ensure ideal exposure and quality. High-contrast colors coupled with huge, understandable sans-serif font styles dramatically boost readability, specifically in high-traffic locations where quick understanding is crucial. forklift signs. Strategic placement at eye level and making use of long lasting products like aluminum or polycarbonate further add to the longevity and effectiveness of these indications. Moreover, adherence to OSHA and ANSI guidelines not just standardizes security messages however additionally reinforces conformity. To completely comprehend the intricacies and finest techniques included, numerous added factors to consider benefit closer interest.

Shade and Contrast

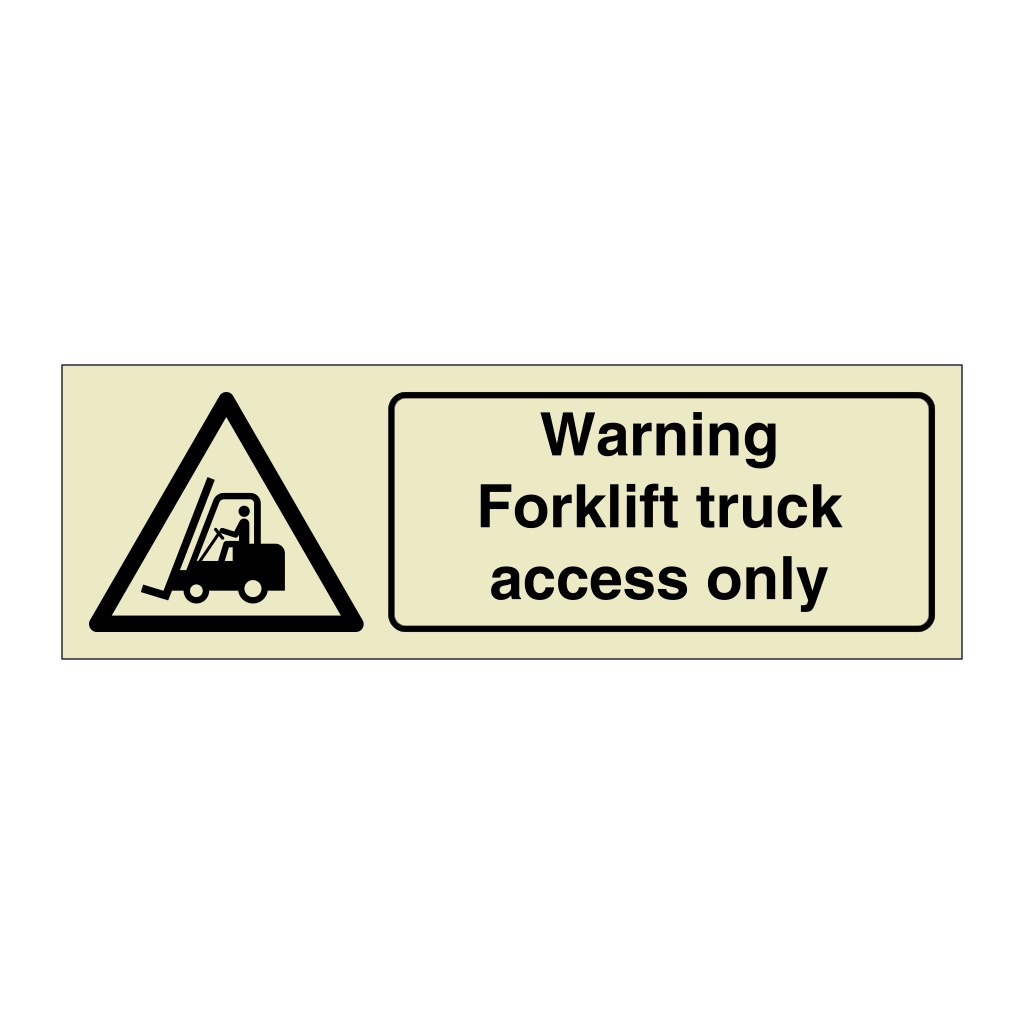

While creating forklift safety indications, the choice of shade and comparison is vital to ensuring exposure and effectiveness. The Occupational Safety and Wellness Administration (OSHA) and the American National Specification Institute (ANSI) provide standards for making use of colors in security signs to systematize their significances.

Efficient comparison in between the background and the message or symbols on the sign is similarly essential. High comparison makes sure that the sign is legible from a distance and in differing lights conditions. Black text on a yellow background or white text on a red background are combinations that stand out plainly. Additionally, using reflective materials can improve presence in low-light settings, which is frequently a factor to consider in stockroom settings where forklifts operate.

Using proper color and comparison not just abides by regulative criteria yet likewise plays a vital role in maintaining a safe workplace by making certain clear communication of threats and instructions.

Font Style Size and Style

When designing forklift safety indicators, the option of font style size and style is essential for making certain that the messages are clear and rapidly recognized. The key objective is to improve readability, particularly in atmospheres where fast details processing is important. The font size must be huge sufficient to be checked out from a range, fitting varying sight problems and making certain that workers can comprehend the indication without unnecessary strain.

A sans-serif typeface is usually recommended for safety and security indicators due to its clean and uncomplicated appearance, which boosts readability. Font styles such as Arial, Helvetica, or Verdana are often favored as they lack the detailed details that can cover crucial details. Consistency in font style throughout all safety and security indications help in creating an attire and expert appearance, which even more enhances the relevance of the messages being shared.

Furthermore, focus can be attained with critical use of bolding and capitalization. By very carefully choosing proper typeface sizes and designs, forklift security indications can properly communicate vital safety and security info to all employees.

Positioning and Exposure

Making sure ideal positioning and exposure of forklift security indications is vital in industrial setups. Appropriate indicator placement can substantially minimize the risk of crashes and enhance general work environment safety.

Indications must be well-lit or made from reflective products in dimly lit locations to ensure they are noticeable at all times. By thoroughly thinking about these aspects, one can make sure that forklift safety signs are both reliable and noticeable, thus fostering a safer working environment.

Material and Resilience

Choosing the best materials for forklift safety signs is crucial to ensuring their longevity and performance in industrial environments. Given the severe conditions usually encountered in storehouses and manufacturing centers, the materials chosen should endure a range of stressors, including temperature variations, moisture, chemical direct exposure, and physical influences. Long lasting substratums such as aluminum, high-density polyethylene (HDPE), and polycarbonate are prominent options because of their resistance to these aspects.

Aluminum is renowned for its effectiveness and deterioration resistance, making it a superb selection for both interior and outside applications. HDPE, on the other hand, offers remarkable effect resistance and can sustain extended exposure to rough chemicals without breaking down. Polycarbonate, known for its high impact toughness and clearness, is usually utilized where visibility and longevity are vital.

Similarly vital is the kind of printing used on the signs. UV-resistant inks and safety layers can dramatically boost the life-span of the signs by stopping fading and wear caused by extended direct exposure to sunshine and other ecological variables. Laminated or screen-printed surfaces offer extra layers of protection, making certain that the crucial security details continues to be readable with time.

Investing in premium products and durable production refines not only extends the life of forklift safety indications Go Here yet also reinforces a society of security within the office.

Conformity With Regulations

Adhering to regulatory requirements is vital in the layout and release of forklift safety and security indicators. Conformity ensures that the signs are not only effective in conveying essential safety and security details yet additionally fulfill lawful commitments, therefore mitigating possible responsibilities. Numerous companies, such as the Occupational Security and Health And Wellness Management (OSHA) in the USA, supply clear standards on the requirements of safety signs, including color pattern, message dimension, and the addition of generally recognized symbols.

To abide with these guidelines, it is crucial to perform a complete evaluation of suitable requirements. OSHA mandates that security signs have to be noticeable from a distance and consist of certain colors: red for threat, yellow for caution, and green for safety and security directions. Additionally, sticking to the site American National Criteria Institute (ANSI) Z535 series can further boost the efficiency of the signs by systematizing the layout components.

In addition, regular audits more info here and updates of safety indicators ought to be executed to make sure recurring conformity with any type of adjustments in policies. Involving with accredited safety and security experts throughout the style stage can also be valuable in guaranteeing that all governing demands are fulfilled, and that the indications offer their designated objective successfully.

Conclusion

Designing efficient forklift security signs requires mindful interest to shade contrast, font style size, and design to ensure ideal presence and readability. Strategic placement at eye degree in high-traffic areas improves recognition, while the use of long lasting materials makes sure long life in various environmental problems. Adherence to OSHA and ANSI guidelines standardizes security messages, and including reflective products increases exposure in low-light circumstances. These factors to consider jointly add to a much safer working setting.